At Atlas Testing Labs and Services (Nova Scotia) Ltd., we understand the critical role that non-destructive testing plays in maintaining the efficiency and safety of the pulp and paper industry. With over four decades of experience, our expert team is equipped to handle the unique challenges of this sector, ensuring that your operations run smoothly and without interruption.

Our comprehensive range of services includes the inspection and maintenance of essential components such as steam piping, storage tanks, pulp refiners, boilers, and paper machines. We employ advanced techniques like Magnetic Particle Inspection (MPI), Liquid Penetrant Inspection (LPI), and Ultrasonic Inspection to detect potential issues before they become costly problems.

Ensuring the optimal performance of steam piping and boilers is vital to reducing the risk of leaks and failures that could disrupt production. Our precise inspection methods help maintain the integrity of these systems. Similarly, we provide thorough inspections of storage tanks to detect corrosion and structural weaknesses, ensuring the safe storage of materials.

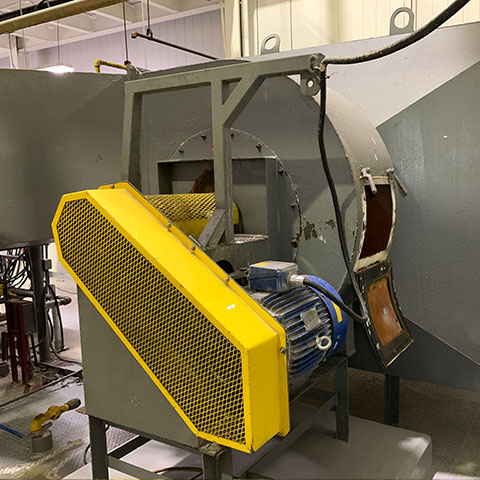

For pulp refiners, our non-destructive testing services help maintain the quality and consistency of your pulp production, extending the lifespan of your equipment. Regular maintenance and inspection of paper machines are also crucial for continuous operation. Our team uses the latest NDT techniques to identify wear and tear, preventing unexpected downtime and maintaining high productivity levels.

Trust Atlas Testing Labs and Services to keep your pulp and paper operations running efficiently and safely. With our dedicated support and cutting-edge technology, you can focus on producing high-quality paper products while we ensure your equipment’s reliability and longevity.